Firm QuantumScape has reported promising results in the prototype tests of so-called solid-state batteries for electric vehicles, a division of the automaker Volkswagen, according to The Autopian. This technology assures a higher energy density compared to existing batteries, reduces fire risk by eliminating flammable electrolytes, and promises better durability during cyclic charging, potentially extending battery life.

PowerCo specializes in battery technology and manufacturing. During several months of testing, QuantumScape’s battery prototype maintained 95% of its original capacity after 1000 charging cycles. This achievement stands out as Volkswagen aimed for a 20% capacity loss after 700 charging cycles in this developmental phase.

The new battery technology also meets the benchmarks for charging speed, self-discharge, and safety. If applied in an electric car achieving a range of 500 to 600 kilometers, the 1000 charging cycles would cover a distance of 500,000 kilometers while retaining 95% of the initial capacity, exceeding the lifespan of most vehicles.

However, it’s crucial to note that these projections are somewhat idealized, assuming 1000 full charging cycles and maximum range reached each time. Regardless, this technology signals potentially outstanding battery longevity, surpassing current electric vehicle standards.

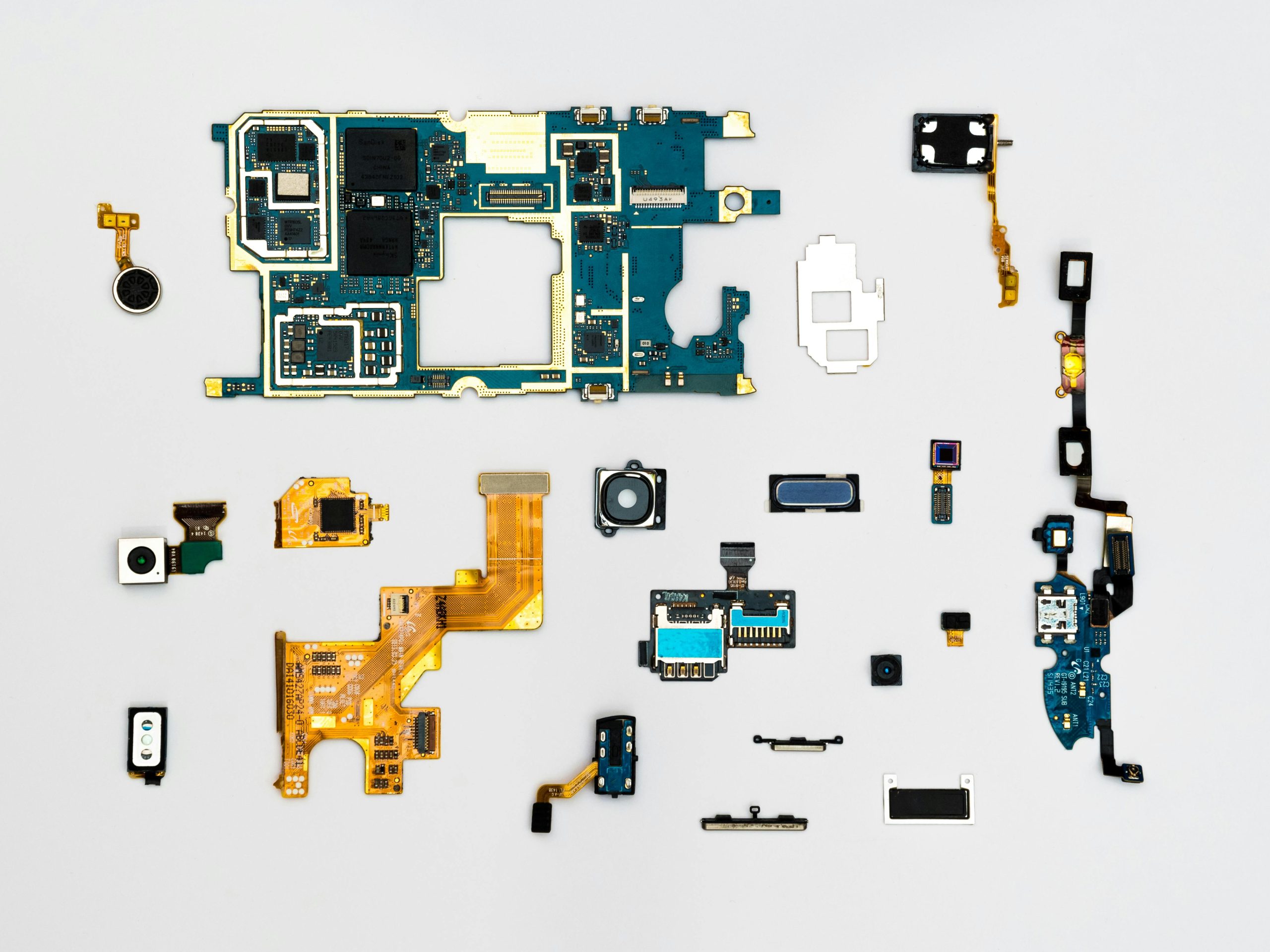

Unlike lithium-ion batteries, solid-state batteries employ lithium but differ by having a solid electrolyte rather than liquid or gel-based ones. This design allows the use of metallic lithium as an anode material, storing more energy compared to current battery anode materials of the same weight. Removing the flammable liquid electrolyte reduces fire risk and facilitates faster charging due to lower ignition risk from overheating.

Various companies are actively pursuing this technology, but challenges persist regarding size and reliability. Nevertheless, QuantumScape seems to have tackled a major issue: preventing the formation of lithium dendrites, fiber-like structures inside the cell that could rapidly degrade the battery.

However, the imminent mass production of these new cells in commercially available vehicles might not occur soon. Even though QuantumScape claims that its 24-layer test cell aligns with the design intended for mass production, it remains a prototype.

Establishing a cost-effective large-scale production process is a demanding task. Many automakers currently struggle with ramping up production of conventional batteries. If QuantumScape manages to devise reliable semiconductor cells and a suitable manufacturing process, there’s significant potential.

Should these cells endure real-world conditions and become cost-competitive, their higher energy density—indicating how much energy is stored in one kilogram of mass or liter of volume—could revolutionize all electric vehicles using them. It would enable manufacturing vehicles with much greater range than competitors or similar range but significantly lower weight, as highlighted by the source.

Photo source: www.pexels.com

Author of this article

WAS THIS ARTICLE HELPFUL?

Support us to keep up the good work and to provide you even better content. Your donations will be used to help students get access to quality content for free and pay our contributors’ salaries, who work hard to create this website content! Thank you for all your support!

OR CONTINUE READING